How to Measure a Curve

Every piece of curved and bent glass that we manufacture is completely custom to your unique specs.

We start by building a comprehensive quote based on your curved glass design and application. Once you’re ready to move forward with us, we need to obtain the templates from which your curved glass will be produced. For smaller projects like cabinet doors and curved glass windows, we typically ask for a frame or a tracing of the curvature we need to produce. This can easily be done on coroplast or cardboard, or you can provide the broken glass we’re replacing. For larger projects like curved glass staircases and railings, we require 2D AutoCAD drawings in DXF or DWG format*. For projects like curved glass boat windshields and car windows, we require a physical template or a full-size 3D drawing.

*If you cannot produce these drawings, we’ll do them for you and get you to approve them before we go into production. Onsite 3D laser measuring and drawing packages are also available for larger, more complex jobs requiring extra precision. Click here for more information about our 3D Laser Measuring Services

During the next step in production, we take the curvature for each piece and building a custom mold to match the desired shape. As part of our value add, we can store a mold for up one year making it easy for you to replace pieces as needed.

See below for a list of helpful terms for measuring curved glass.

MEASURING TERMS

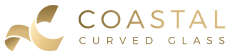

When specifying a radius, always specify which surface the radius is being measured to (inside face or outside face of the glass). If unsure, measure it to the center of the surface(s).

Diameter: The distance across a circle (Or: 2x the radius)

Radius: The distance from the center of a circle to the edge of the circle (Or: 1/2 the diameter)

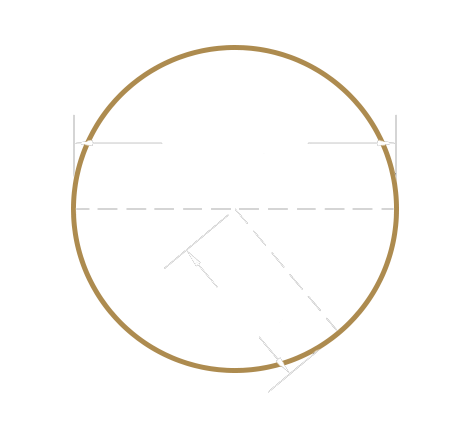

Arc Length (Girth): The measurement following along a curved surface from edge to edge

Chord Length: A straight line between the two end points of the curve

Height: Straight side of the glass

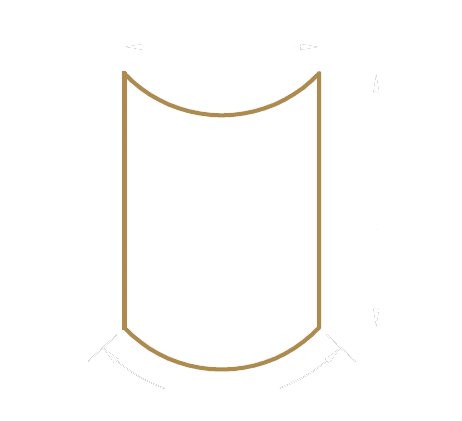

Convex: The surface that curves outwards

Concave: The surface that curves inwards

Depth (of Bend): Taken at a 90 degree angle, the distance between a flat surface (Chord) and the mid-point of the curve.

Technical Specifications

Coastal Curved Glass manufactures the vast majority of our glass in our Vancouver warehouse through our highly trained and experienced team. There are however some jobs that we choose to source from an industry partner as the requirements are either outside our production capabilities due to size or volume requirements.

Although we can produce curved glass that’s up to 1” thick, it’s important to note that the thicker the glass and the tighter the curve, the more chance there is for optical distortion. We work with you to review your design and recommend the best option for safety and optical quality.

We are proud to be named the exclusive North American supplier for one of the leading European manufacturers of curved glass. This partnership allows us to provide you with the local support you require when working on complex, large-scale jobs. This can include onsite measurements and glass patterns, the handling of all communications to ensure deadlines and local building code requirements are met, invoicing, shipping, delivery and even installation.

In-house production specs:

-

Glass Thickness: 2 – 24mm

-

Glass Sizes: Minimum 1” x 1”, Maximum 90” x 155”

-

Minimum radius: 3”

-

Glass Type:

Annealed, Laminated, Chemically Strengthened, Insulated Units, Tempered, Tempered + Laminated -

Features:

J and S shape bends, anti-reflective glass, non-radius curved glass, spherical bends, switchable glass, sandblasted glass, screen-printed, Low Iron (ultra clear), LowE (energy efficient), images laminated in glass, glass tints or interlayers of any color

Partner production specs:

-

Glass Thickness: 2 – 24mm

-

Glass Sizes: Maximum 110” x 228” (tempered),

Maximum 80” x 165” (tempered + laminated) -

Minimum radius: 18”

-

Glass Type: Tempered, Laminated + Tempered,

Heat Strengthened, Insulated Glass Units -

Features: Jumbo glass, digitally printed frit, laser etching

CONTACT US NOW TO BRING YOUR DESIGN TO LIFE - CALL NOW: 604.457.4477

If you have questions about a curved glass project, contact us today & we would be happy to assist.