Annealed Glass

The annealing of “float” (non-treated) glass is a process that involves slowly cooling hot glass objects after formation, to relieve any internal stresses created during the manufacturing process. The annealing of glass is crucial to the strength, durability and reliability of the finished product. Glass that has not been properly annealed can be likely to crack or shatter under small pressure, stress, or environmental changes.

Recommended applications:

cabinet doors,

decorative art glass sculptures,

certain residential windows

Recommended applications:

passenger vehicle windows,

shower doors, railings and staircases,

architectural glass doors and tables.

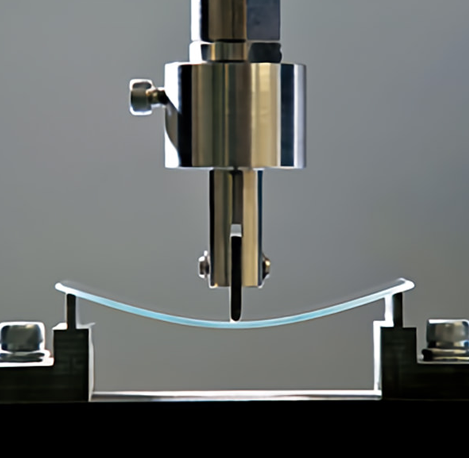

Tempered Glass

Tempered glass is one form of “safety glass”. The original glass is treated thermally to increase its strength, making it a stronger and safer form of glass which is often required for many applications. Tempering involves heating the glass to a point just before melting temperature, and then quenching it rapidly. The stress caused by this rapid quench will result in a significant increase in strength. If broken, the glass will crumble into tiny blunt pieces, rather than jagged shards (as annealed glass would).

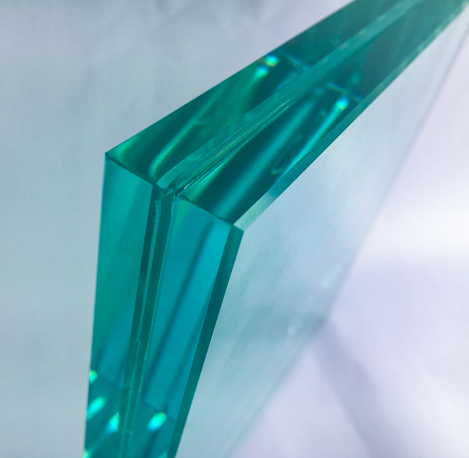

Laminated Glass

Laminated glass is another form of “safety glass” that consists of two or more layers of glass held together by an interlayer typically made of SentryGlas, PVB or EVA. This interlayer (which can be clear or coloured) keeps the layers of glass bonded when broken, preventing the glass from breaking into jagged shards, but rather a crackled pattern. Laminated glass is a safer choice in areas that pose a security concern since the glass will remain intact, even when broken. This type of glass is especially prevalent in jewelry stores, hurricane-prone areas, and any area where safety is of the utmost concern. Laminated curved glass has the highest optical quality possible, due to the more controlled manufacturing process.

Recommended applications:

skylights, windshields,

exterior storefronts,

glass walls, windows, railings

Recommended applications:

this type of treated glass is suitable for most applications but is especially common for boat/ yacht windows or when optical quality is of the utmost importance.

Chemically Strengthened Glass

Chemically strengthened glass has been treated for increased strength and durability, making it typically six to eight times the strength of annealed glass. The glass is produced by being submersed into a chamber containing a heated potassium salt which causes smaller sodium ions in the glass surface to be replaced by larger potassium ions from the solution. This replacement of ions causes the surface of the glass to be in a state of compression and the core in compensating tension. Chemically strengthened glass is not considered safety glass as it will have a break pattern similar to annealed glass, but we can laminate it if safety glass is required.

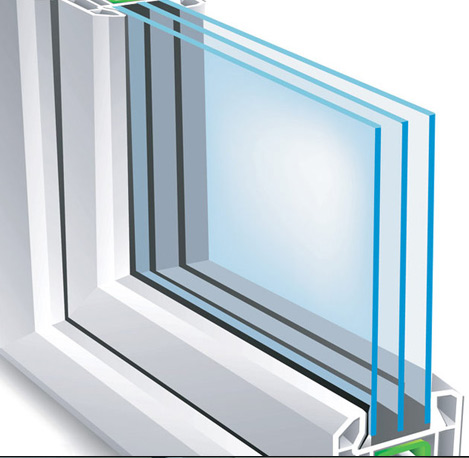

IGUs (Insulated Glass Units)

Insulated glass consists of double-pane or triple-pane glass separated by a spacer bar to reduce heat transfer. We manufacture insulated glass units in-house to our clients’ specifications. Insulated glass can include annealed, thermally tempered, chemically strengthened, or laminated glass options. A wide variety of LowE coatings can be utilized to further increase energy efficiency.

Coastal Curved Glass is proud to be a Vitro Certified Fabricator and a Saint-Gobain Certified Fabricator. Our Insulated Glass Units have gone through rigorous testing and have received IGCC approval.

Recommended applications:

windows, display cases,

refrigeration cases, wine rooms

Recommended applications:

any application you like!

Decorative Glass

There’s a trend in both residential and commercial buildings to include decorative art glass in place of walls or clear glass. There are multiple applications for treating glass to get the desired effect, but the most common options we provide include screen printed glass, sandblasted glass, and specialty ordered printed or coloured interlayers.

Screen printed glass can be made with any design you want by simply printing a layer of ceramic ink onto the surface of glass through a screen mesh.

Etched and sandblasted glass provide excellent durability and design. Etched glass is typically created by applying acidic, caustic, or abrasive substances directly to the glass whereas sandblasted glass is produced when abrasive media is accelerated through a blasting nozzle by means of compressed air.

Hardware

Coastal Curved Glass can see through your completed project, which often includes the ordering and installation of all chosen glass hardware. We are a supplier for many industry leading hardware manufacturers, allowing us to source the highest-quality and most complete catalogue of hardware to make your design stand out.

Glass Channels

Custom aluminum and stainless-steel extrusions can be curved using a stretch form process for a guaranteed fit. We will work with our preferred suppliers to create the total package for your curved glass design.

We test-fit the glass and channels at our production facility to ensure there is a perfect fit when the products arrive on-site.

CONTACT US NOW TO BRING YOUR DESIGN TO LIFE - CALL NOW: 604.457.4477

If you have questions about a curved glass project, contact us today & we would be happy to assist.